1. Introduction

Producing hydrogen at scale involves complex processes, including the integration of variable renewables, electrolysis, storage, transport, and end-use, each with its own technical and economic constraints. In the early stages of a green hydrogen or Power-to-X (P2X) project, decision-makers face numerous questions:

- What type of hydrogen system should be developed?

- Where is the optimal location based on renewable potential and infrastructure?

- What should be the production capacity?

- Which end-use markets should be targeted?

- What are the expected costs and economic returns?

In many regions, particularly in developing countries, the hydrogen energy sector has encountered numerous challenges. Project development is often hindered by fragmented and incomplete data on resource availability, supplier networks, and financial parameters such as CAPEX and OPEX. Despite the abundance of renewable energy resources in regions like Africa and South America, their utilization remains limited due to the lack of advanced tools for optimal integration into hydrogen systems. Decision-making processes are therefore time-consuming, inefficient, and marked by uncertainty leading to higher financial risks and limited scalability of projects.

Furthermore, no digital solution has yet provided comprehensive interactive mapping capabilities that allow stakeholders to evaluate project locations globally while considering suppliers, infrastructure, and resource availability.

The sustainability revolution will be powered by digital technologies. Advancing the hydrogen economy requires innovative tools, rapid scale-up, and the deployment of advanced digital strategies to overcome operational complexity. Digital solutions play a pivotal role in accelerating hydrogen innovation by:

- Improving electrolysis and conversion processes.

- Streamlining the research-to-construction pipeline.

- Rigorously evaluating technological alternatives.

- De-risking storage, transport, and fuel cell deployment.

Partners

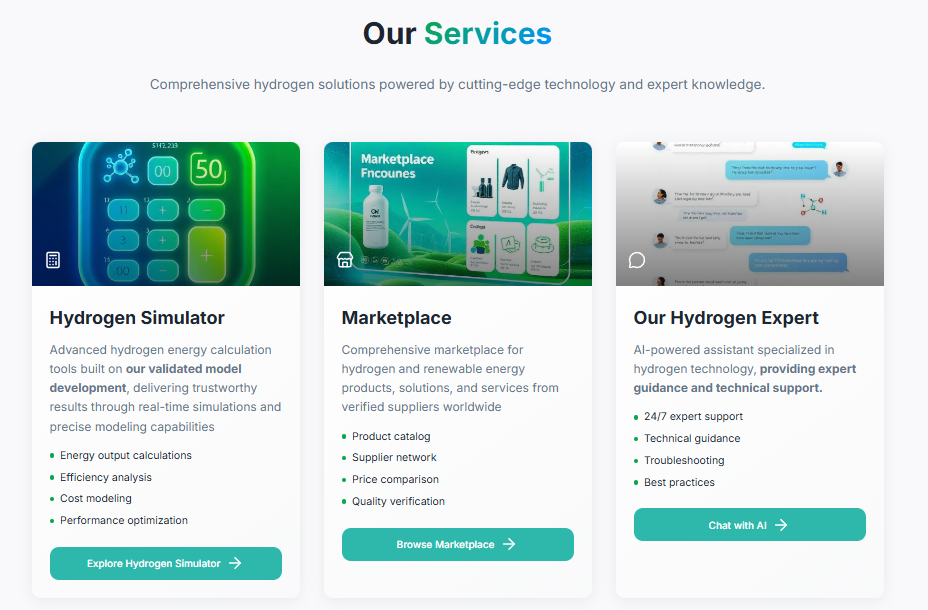

1.1 Purpose of H2CHAIN

To address the critical gaps and limitations of existing hydrogen modeling tools, this research paper presents H2CHAIN, an innovative digital software platform designed to optimize the entire hydrogen value chain. The platform offers a user-centric interface composed of interconnected modules that guide users through each stage of hydrogen system design and analysis. At its core, H2CHAIN features a calculator module that enables users to simulate hydrogen production by selecting renewable energy sources, estimating production outputs, and integrating downstream components such as compressors, storage tanks, and distribution infrastructure. The products module provides access to a curated database of hydrogen-related technologies, including electrolyzers, compression systems, and both pressurized and cryogenic storage solutions, allowing users to evaluate technology choices based on performance and sustainability criteria.

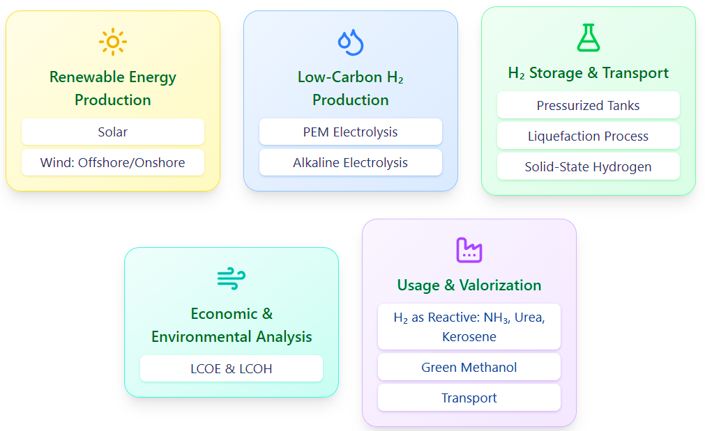

1.2 Scope and Applications

H2CHAIN covers production, storage, and utilization stages while supporting the integration of various renewable energy sources, including solar, wind, and marine energy. The objective of this research is to develop and validate a comprehensive, user-friendly, and modular platform that empowers stakeholders to design, evaluate, and deploy hydrogen projects more efficiently and cost-effectively.

1.3 System Requirements

H2CHAIN is designed as a web-based platform, which means users do not need to install or configure any specialized software or hardware. The main requirement is a stable, high-speed internet connection, as the platform relies on real-time data exchange and cloud-based computation.

Minimum Requirements

- Device: Desktop or laptop computer (Windows, macOS, or Linux).

- Browser: Latest version of Chrome, Firefox, Safari, or Edge.

- Internet Connection: Broadband connection with at least 10 Mbps download/upload speed.

Recommended Requirements

- Device: Modern computer with at least 8 GB RAM and a multi-core processor for smooth visualization.

- Browser: Chrome or Firefox (latest version) for full compatibility.

- Internet Connection: Stable connection ≥ 25 Mbps, especially when running simulations with large datasets or interactive maps.

Note

Since H2CHAIN runs entirely on the cloud, users are not limited by local computing power, but a strong and stable internet connection is critical to ensure fast response times and seamless user experience.

2. Getting Started

2.1 Installation and Setup

H2CHAIN is a web-based platform, meaning no local installation is required. Users only need a modern web browser (e.g., Google Chrome, Microsoft Edge, or Firefox) and a stable internet connection. Since the computations and simulations are performed on the server side, there are no special hardware requirements on the user's computer.

Steps to access H2CHAIN:

- Navigate to the official H2CHAIN web portal (URL provided by the development team).

- Create an account using your institutional or personal email address.

- Verify your email and log in with your credentials.

- Once logged in, you can immediately begin configuring hydrogen value chain projects.

Note

A reliable high-speed internet connection is highly recommended, as the platform processes large datasets and renders interactive results in real time.

2.2 User Interface Overview

The H2CHAIN interface is designed to be intuitive and modular, allowing users to move seamlessly from one stage of the hydrogen value chain to another. The main components include:

- Navigation Panel (left sidebar): Provides quick access to modules such as Resource Assessment, Production, Storage, Transport, and End-Use Applications.

- Workspace Area (center): Displays the active module, with input forms, simulation results, and visualizations.

- Interactive Maps (top or integrated in modules): Allow users to explore renewable resource availability, infrastructure, and project sites.

- Toolbar (top navigation): Contains account settings, project management tools, and help/documentation links.

- Output Dashboard: Provides results in graphical, tabular, and report formats for analysis and export.

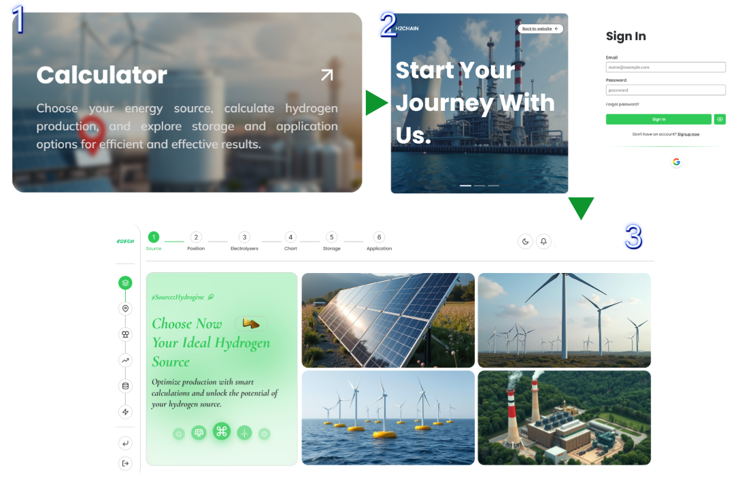

2.3 First Steps with H2CHAIN

When first entering the platform, users are encouraged to:

- Create a new project by defining the geographic location (e.g., Dakhla, Morocco) and project timeframe.

- Select the hydrogen pathway of interest (e.g., green hydrogen for methanol, ammonia, or direct transport use).

- Input initial parameters such as system size, technology types (PV, wind, electrolyzers), and assumptions (CAPEX, OPEX, efficiencies).

- Run a baseline simulation to generate preliminary outputs on hydrogen production, storage needs, transport logistics, and potential costs.

- Explore results via dashboards, scenario comparison, and mapping tools.

Tip: Start with a smaller "test project" to get familiar with the workflow before setting up full-scale simulations.

📺 Video Tutorial

For a comprehensive visual introduction to H2CHAIN, watch our detailed video tutorial that walks through the platform's key features and demonstrates the complete hydrogen simulation workflow.

3. Design and Architecture of the H2CHAIN Platform

The H2CHAIN platform was developed in response to several practical limitations encountered during field research on green hydrogen production. Many existing tools are closed source, overly technical, fragmented, or focus only on specific segments of the hydrogen value chain. H2CHAIN addresses this gap by offering an open-access, user-friendly, and comprehensive simulation environment designed to support both existing hydrogen infrastructures and new project development. The platform provides two main functionalities. First, it enables real-time monitoring of existing assets. Second, a project simulation module allows users to define a hydrogen production target, and the platform automatically determines the optimal system configuration.

Table 1. Key Strengths of H2CHAIN Compared to Other Tools

| Aspect | H2CHAIN | Other Tools |

|---|---|---|

| Web accessibility (no installation) | Yes, fully web-based platform | Most are desktop-based, Excel-based, or under license |

| Geospatial integration (GIS) | Built-in, with interactive visualization | GeoH2 provides it, but lacks a user-friendly interface |

| Full techno-economic simulation | Includes electrolysis, storage, transport, and end-use modeling | H2FAST focuses only on finance; Fichtner is closed-source |

| AI-based forecasting (production, weather, demand) | AI forecasting integrated for dynamic scenarios | None of the others include AI-based forecasting |

| Multi-energy vector compatibility (Power-to-X) | Can be extended to model H2, NH3, e-fuels | Only H2Integrate partially supports this |

| Open, modular, and accessible to non-experts | Designed for project developers, public agencies, and planners | Most tools require experts or consultants to operate |

4. Core Functionalities of H2CHAIN

4.1 User Interface: Web Accessibility and Usability

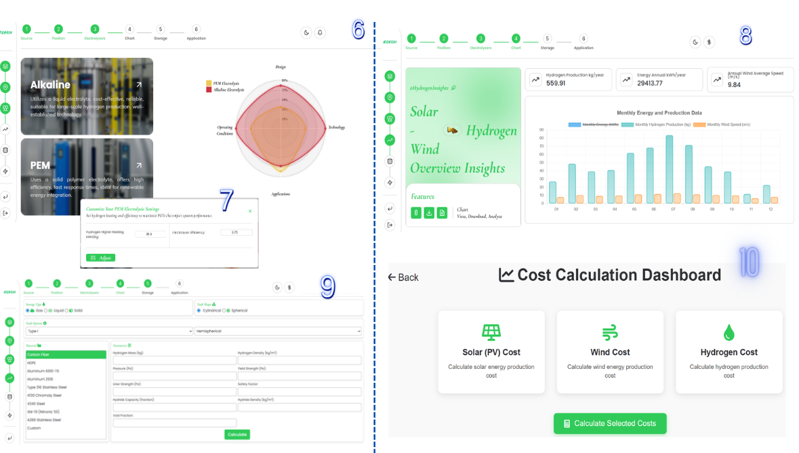

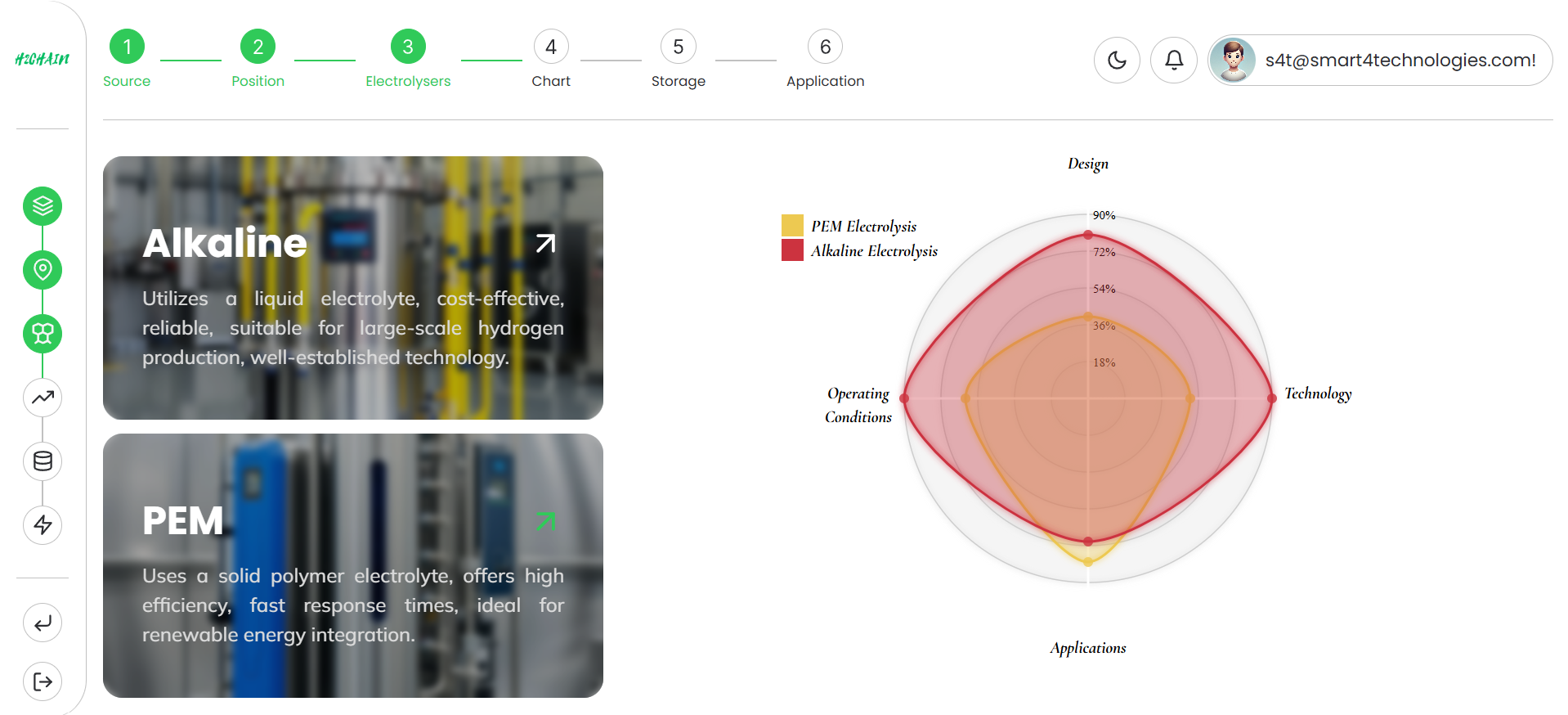

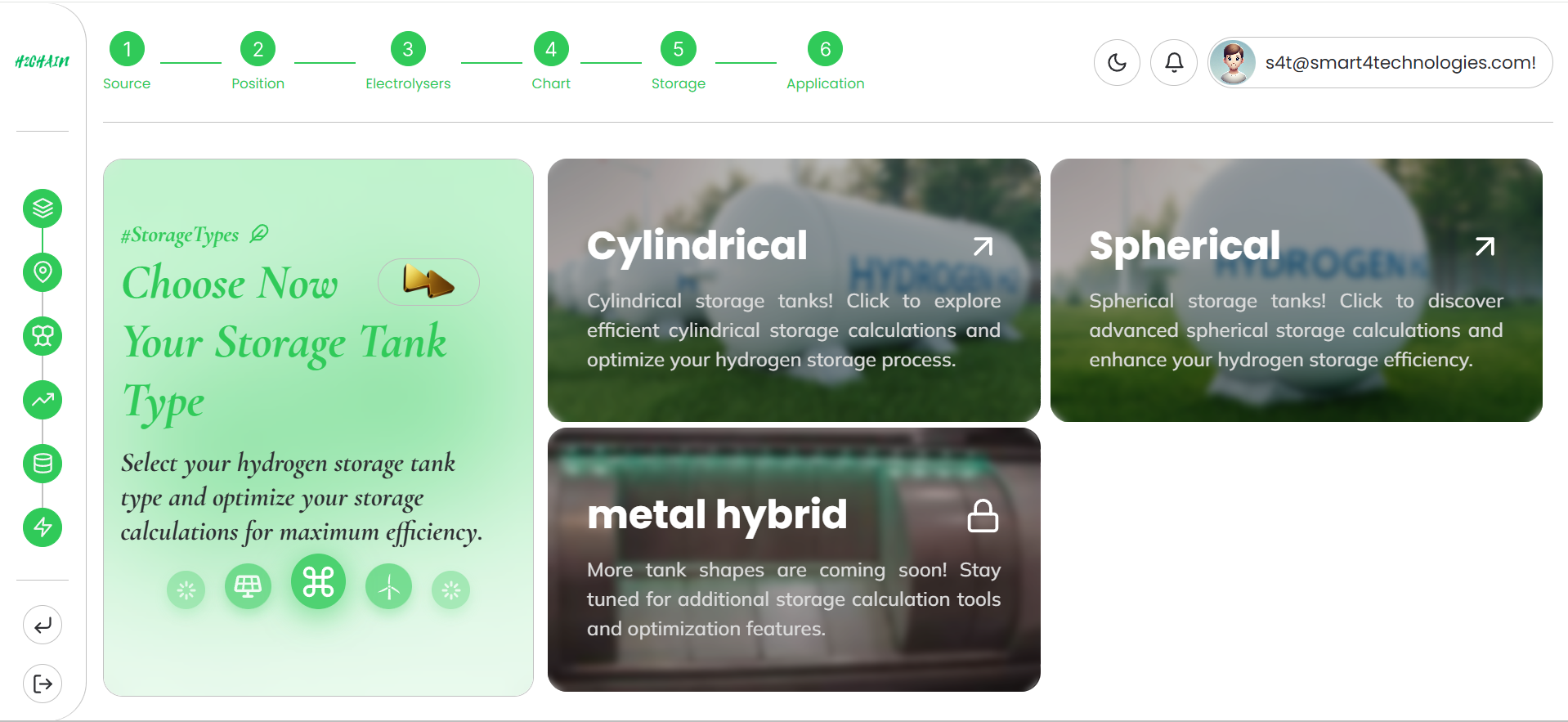

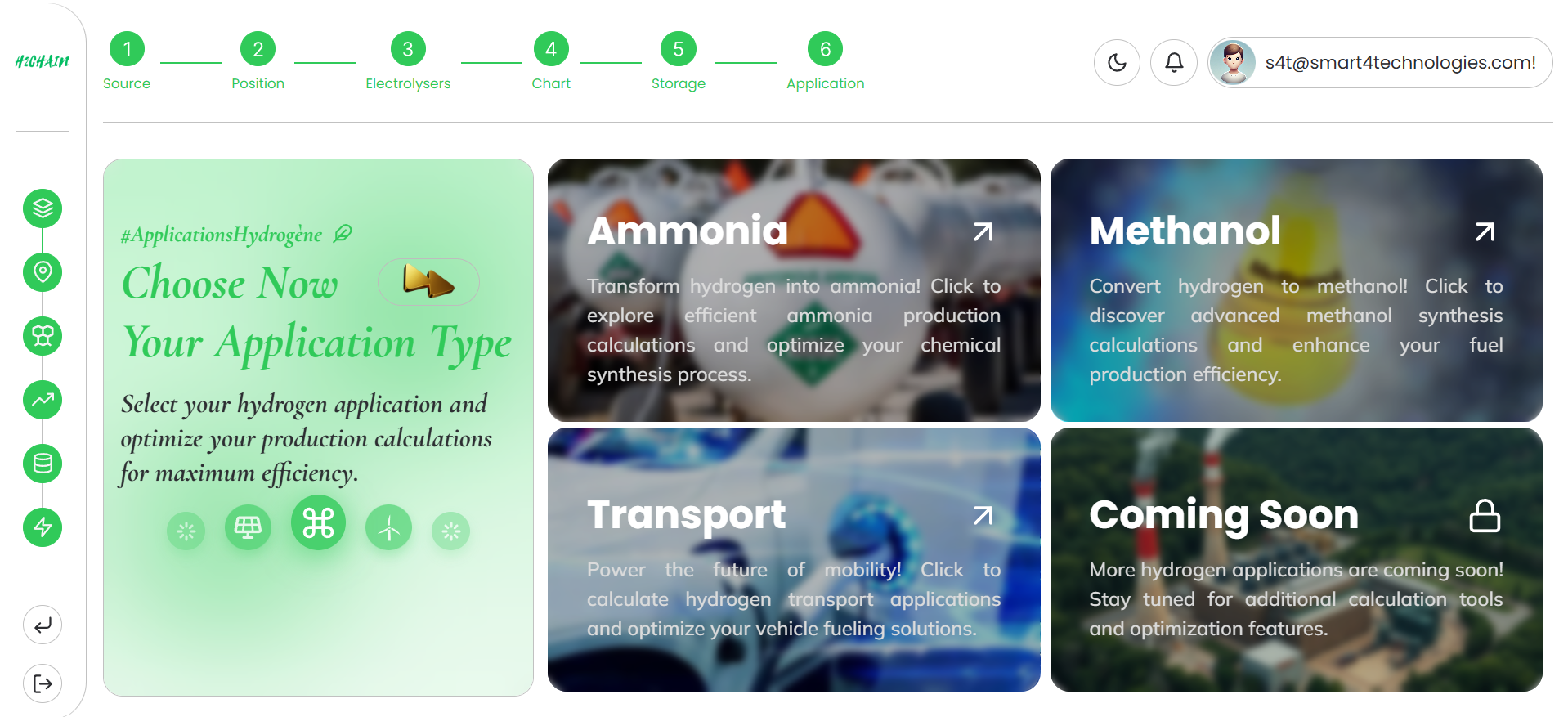

The H2CHAIN platform has been thoughtfully designed to ensure a seamless, intuitive, and accessible user experience. From the very first interaction, users are guided through the platform with clear navigation and visual cues. The main entry point is the “Calculator” module. Once logged in, users follow a structured, step-by-step workflow divided into six intuitive stages: Source, Position, Electrolyzers, Chart, Storage, and Application. The interface also supports both light and dark modes and is responsive across devices.

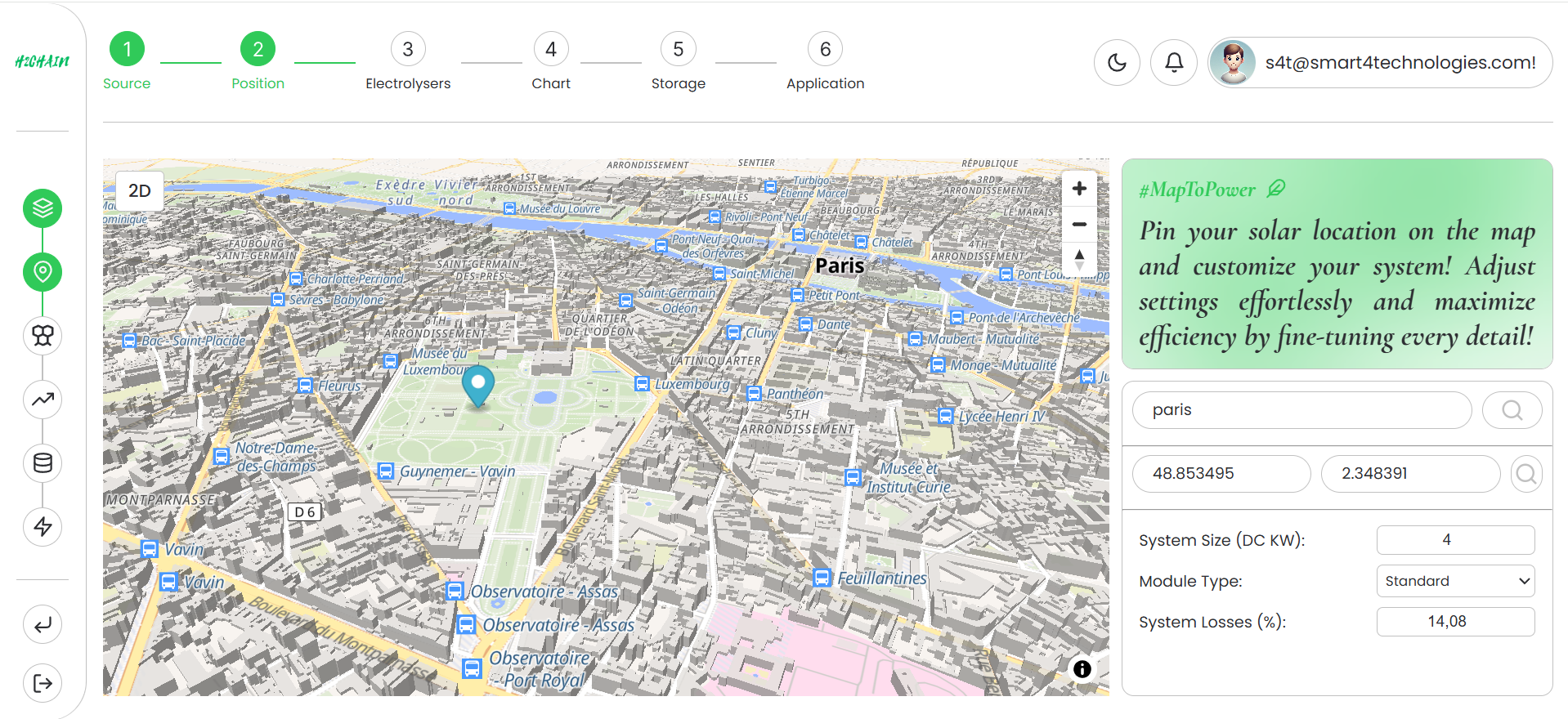

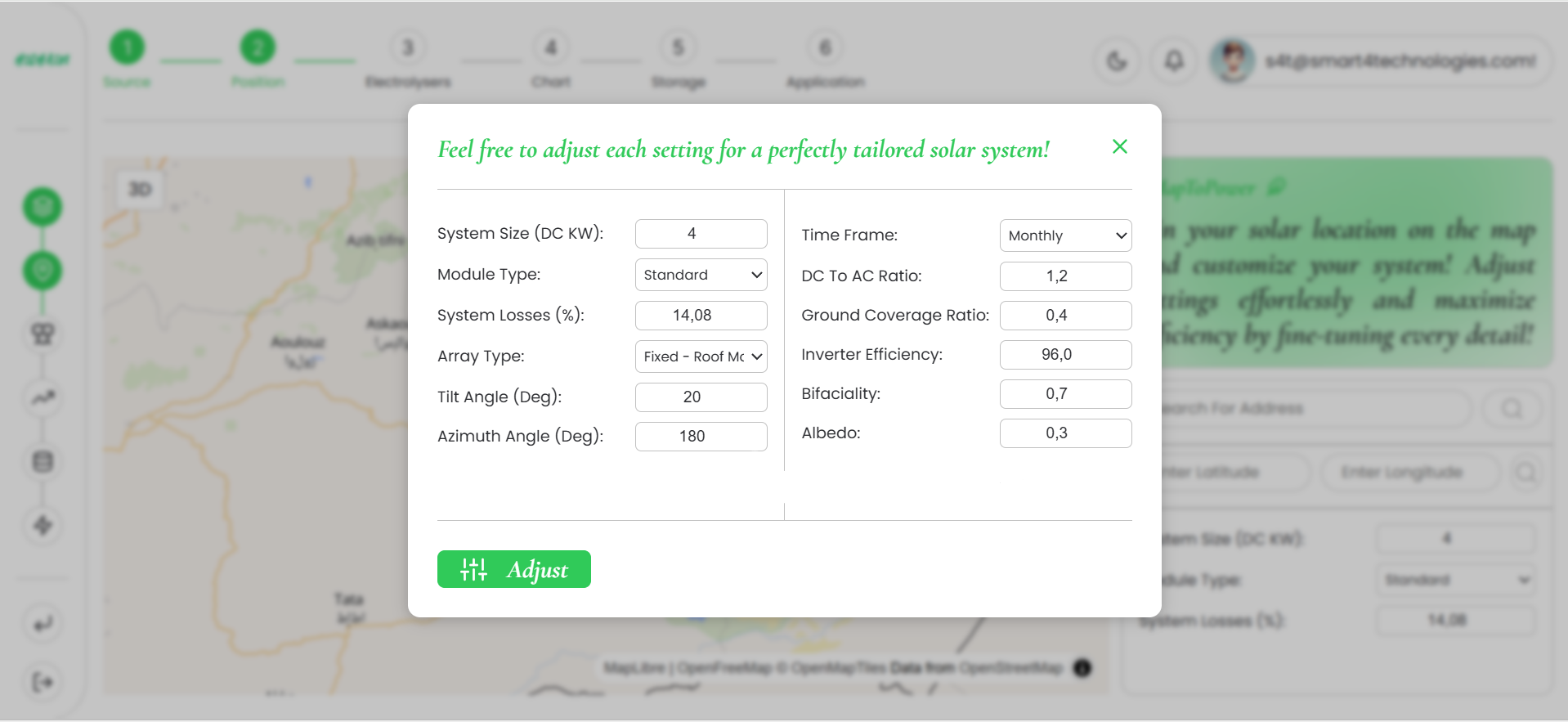

4.2 Interactive Geospatial Analysis: Smart Site Selection

The H2CHAIN platform integrates an advanced geospatial analysis tool to facilitate the intelligent selection of the hydrogen production site. In the "Position" step, users can interact directly with an embedded map interface to pinpoint the exact location for system integration. Whether by searching an address or entering precise latitude and longitude coordinates, the platform ensures high flexibility and customization. This interactive map allows users to assess geographic suitability, enabling them to strategically select solar, wind, or hybrid installation sites.

4.3 Multi-Scenario Techno-Economic Simulations

H2CHAIN provides an integrated environment for performing detailed techno-economic simulations across multiple renewable energy configurations. Users can simulate the full hydrogen production value chain starting from solar and wind energy generation, through electrolysis, storage, and ending with application. The platform allows users to customize technical parameters and offers a comparative interface for electrolyzer technologies. A dedicated Cost Calculation Dashboard allows for the evaluation of production costs. Once simulations are complete, H2CHAIN automatically generates clear, structured reports summarizing both the technical setup and financial outcomes, available for download in PDF format.

4.4 Mathematical Modeling and Validated Equations

The mathematical models integrated into the H2CHAIN platform are derived from high-impact scientific publications and supported by our own peer-reviewed research. Each equation has been selected for its reliability and ability to accurately reflect real-world hydrogen production systems. The validation of these models through deep research ensures a high level of confidence in the simulation results.

Table 2: Mathematical models integrated into the H2CHAIN

| Model Component | Equation | Description |

|---|---|---|

| Hydrogen Production | mH₂ = (P_EZ × η) / HHV_H₂ | Mass of hydrogen produced based on electricity input and electrolyzer efficiency. |

| LCOH Calculation | LCOH = (NPV[CAPEX] + NPV[OPEX]) / NPV[H₂ generation] | Levelized cost of hydrogen over system lifetime (in USD/kg). |

| Electrolyzer | η_HHV = (HHV_H₂ × m_H₂) / P_EZ | Efficiency evaluation of different electrolyzer technologies based on the Higher Heating Value (HHV). |

| Storage Sizing | N/A | Determines safe hydrogen storage capacity and tank dimensions. |

4.5 Added Value of the H2CHAIN Platform

Beyond its core modules and algorithmic structure, H2CHAIN introduces several functional advantages that enhance its usefulness and strategic relevance. These added values reflect the platform's capacity to respond to real-world project constraints, facilitate user interaction, and support informed decision-making.

Table 3: Key Feature of the H2CHAIN

| Key Feature | Added Value | Explanation |

|---|---|---|

| Territorial Digital Twin Approach | Location-specific simulation and planning | Unlike generic tools, H2CHAIN integrates regional data (resources, networks, climate, industry) to model projects adapted to local contexts. |

| Expert Support Chatbot | Real-time guidance for energy-related questions | The platform includes a smart chatbot capable of answering user queries on renewable energy, hydrogen, and AI, offering immediate access to scientific knowledge. |

| Cross-Sector Interoperability | Support for use cases across energy, transport, and industry | The modular design allows future integration of sector-specific modules (e.g., ports, ammonia plants), with cross-analysis capabilities in development. |

| Accessibility and Educational Value | Empowering a wide range of users, from policymakers to students | H2CHAIN's intuitive interface and contextual assistance lower the barrier to entry for non-experts, promoting inclusive energy planning and training. |

| Easy to Use and Online Access | No installation required, accessible anytime and anywhere | The platform is fully web-based, enabling users to access all features from any device with an internet connection, simplifying deployment and usage. |

5. Key Parameters Explained

This section provides a detailed explanation of the technical and economic parameters used in H2CHAIN. Understanding these parameters is essential for accurately modeling hydrogen projects and interpreting simulation outputs. Each parameter directly influences system sizing, performance, costs, and sustainability indicators across the hydrogen value chain.

5.1 Solar Energy Inputs

Solar energy inputs are the foundation of hydrogen production in H2CHAIN, as they determine the amount of renewable electricity available for electrolysis. The platform allows users to define parameters such as system size, module type, tilt and azimuth angles, and system losses. These inputs are combined with solar resource data to estimate the annual energy yield.

Table 4: Definition of solar parameters

| Parameter | What it Means | Why it Matters for Hydrogen Value Chain |

|---|---|---|

| System Size (DC kW) | Total installed solar panel capacity in kilowatts (DC). | Sets the maximum electricity available for the electrolyzer, directly influencing hydrogen output. |

| Module Type | Type of solar panel (standard, premium, thin-film). | Different efficiencies change electricity yield → affects cost and volume of hydrogen produced. |

| System Losses (%) | Losses due to wiring, dust, temperature, etc. | Reduces the actual usable electricity sent to hydrogen production. |

| Array Type | How panels are installed (roof, ground, or tracking). | Affects sunlight capture and therefore the stability/quantity of power for hydrogen production. |

| Tilt Angle (°) | Angle of panels relative to the ground. | Optimizes sunlight capture → more electricity available for electrolyzers. |

| Azimuth Angle (°) | Direction panels face (e.g., 180° = south in northern hemisphere). | Impacts daily production profile → influences how steady the electrolyzer runs. |

| DC to AC Ratio | Ratio of installed panel capacity (DC) to inverter capacity (AC). | Ensures efficient conversion and stable AC electricity → crucial for continuous hydrogen production. |

| Inverter Efficiency (%) | Efficiency of converting DC (from panels) to AC (usable electricity). | Higher efficiency means more electricity reaches the electrolyzer. |

| Bifaciality | Ability of panels to generate electricity from both sides. | Increases total generation → more power for hydrogen without more panels. |

| Albedo | Reflectivity of the ground (snow, sand, concrete). | Higher albedo boosts bifacial output → more electricity for hydrogen. |

5.2 Electrolyser Performance Parameters

Electrolysers are at the heart of green hydrogen production, and their performance directly determines efficiency, output, and cost. In H2CHAIN, users can define key parameters such as efficiency, operating pressure, load flexibility, and degradation rates. These factors influence the conversion of renewable electricity into hydrogen and help estimate both annual production and long-term system reliability.

Table 5: Definition of PEM Electrolysis Parameters

| Parameter | What it Means | Why it Matters for Hydrogen Production |

|---|---|---|

| Hydrogen Higher Heating Value (HHV, kWh/kg) | The amount of energy stored in 1 kg of hydrogen (when burned/used). | Defines the energy content of hydrogen. Used to calculate how much usable energy you get from the hydrogen produced. |

| Electrolyzer Efficiency | Ratio of actual hydrogen energy output to the input electricity (typically 65-80%). | Determines how much electricity is needed per kg of hydrogen. Higher efficiency = lower cost per kg H₂. |

Table 6: Definition of Alkaline Electrolysis Parameters

| Parameter | What it Means | Why it Matters for Hydrogen Production |

|---|---|---|

| Eta_AC_DC (AC to DC Efficiency) | Efficiency of converting AC grid/renewable electricity into DC current for electrolysis. | Losses here reduce the net electricity available for splitting water. |

| U_rev (Reversible Voltage, V) | The theoretical minimum voltage needed for water splitting (~1.23-1.48 V depending on conditions). | Sets the baseline energy requirement of electrolysis. |

| F (Faraday's Constant, C/mol) | Charge per mole of electrons (~96,485 C/mol). | Used to calculate the exact relation between electricity input and moles of hydrogen produced. |

| Utn (Thermoneutral Voltage, V) | Voltage where heat and electricity balance in electrolysis (~1.48 V). | Used for efficiency benchmarks — operation above this voltage means extra heat generation. |

| Z (Number of Electrons Transferred) | Number of electrons per molecule split (2 for H₂). | Defines stoichiometry of the electrolysis reaction. |

| N_c (Number of Electrochemical Cells) | Number of cells connected in the electrolyzer stack. | More cells = larger hydrogen production capacity. |

| A_EZ (Effective Cell Area, m²) | The active electrode area per cell. | Larger area = more reaction surface = more hydrogen output. |

| T_EZ (Electrolyzer Temperature, °C) | Operating temperature of the stack (e.g., 80 °C). | Affects reaction kinetics and efficiency — higher temperature usually improves performance. |

5.3 Hydrogen Storage Parameters

Hydrogen storage is a critical link between intermittent renewable supply and continuous downstream demand. In H2CHAIN, the storage module allows users to configure essential parameters such as storage type (compressed gas, liquid hydrogen, or solid-state), pressure levels, tank geometry, material, and safety factors. These inputs determine the storage capacity, footprint, cost, and safety margins of the system.

Table 7 & 8: Definition of General and Gas Storage Parameters

| Parameter | Meaning | Why it Matters |

|---|---|---|

| Hydrogen Mass (kg) | Amount of hydrogen to be stored. | Sets storage requirements and tank size. |

| Hydrogen Density (kg/m³) | Density of hydrogen in chosen phase (gas, liquid, or solid). | Used to calculate hydrogen volume inside the tank. |

| Pressure (Pa) | Storage pressure inside tank. | Defines tank wall thickness and stress; higher pressure needs stronger tanks. |

| Safety Factor (F) | Safety margin applied in stress calculations. | Ensures design is safe under operating pressure. |

| Tank Type | Type I (all-metal), Type III (composite with metal liner), Type IV (composite with polymer liner). | Influences strength, weight, and cost. |

| Endcap Type | Tank end shape: Hemispherical or Semi-Elliptical. | Affects volume efficiency and stress distribution. |

Table 9 & 10: Definition of Liquid and Solid Storage Parameters

| Parameter | Meaning | Why it Matters |

|---|---|---|

| Insulation Type | PU foam, perlite, or vacuum insulation. | Determines thermal losses and boil-off rate. |

| Insulation Thickness (m) | Thickness of thermal insulation layer. | Thicker insulation reduces hydrogen evaporation but increases mass and cost. |

| Hydride Material | Selected hydride compound (from ML-HYDPARK database). | Defines hydrogen storage capacity, density, and operating conditions. |

| Void Fraction | Fraction of empty space inside hydride bed. | Affects effective storage density and tank size. |

| Hydrogen Weight Percent (%) | Mass % of hydrogen stored in hydride. | Higher % means lighter storage per kg H₂. |

5.4 End-use applications inputs

The final stage of the hydrogen value chain involves defining its end-use applications. In our software, three priority applications were selected based on market demand and industrial relevance: transportation, green ammonia, and green methanol.

Table 11: Definition of Methanol Application Parameters

| Category | Parameter | Meaning | Why it Matters |

|---|---|---|---|

| Feedstock | H2 Feed (kg/s) | Flow rate of hydrogen supplied to methanol synthesis. | Determines how much methanol can be produced. |

| Feedstock | CO2 Feed (kg/s) | Flow rate of captured carbon dioxide supplied. | CO2 is the carbon source; availability limits methanol output. |

| Reaction | Stoichiometric Ratio (H₂:CO₂) | Required balance of hydrogen to CO₂ (theoretical ~3:1). | Ensures correct chemical reaction; imbalance reduces efficiency. |

| Reaction | Conversion Efficiency (%) | Fraction of input reactants that actually convert into methanol. | Defines how effective the reactor is; higher = less waste. |

Table 12: Definition of Ammonia Application Parameters

| Category | Parameter | Meaning | Why it Matters |

|---|---|---|---|

| Feedstock | H2 Feed (kg/s) | Flow rate of hydrogen entering the Haber-Bosch process. | Determines how much ammonia can be produced. |

| Feedstock | N2 Feed (kg/s) | Flow rate of nitrogen supplied (from air separation). | Nitrogen is the second essential reactant; limits production if insufficient. |

| Reaction | Stoichiometric Ratio (H₂:N₂) | Theoretical ratio of 3:1 for NH₃ synthesis. | Must be maintained for optimal conversion efficiency. |

Table 13 & 14: Transportation Parameters and Calculator Logic

| Parameter / Field | What it Means | Why it Matters |

|---|---|---|

| Fuel Cell Type (PEMFC, SOFC, etc.) | Technology selector driving info text + starting efficiency. | Determines operating temp behavior and default system efficiency. |

| System efficiency (0-1) | End-to-end efficiency from H₂ at tank to electric at wheels/load. | Converts load energy → required H₂ energy at tank. |

| Energy at wheels (kWh) | Road: (Intensity kWh/100km) × (Range/100); Power: Power (kW) × Hours. | Base service energy to be delivered. |

| Energy at tank (kWh) | Energy at wheels ÷ System efficiency. | Accounts for Fuel Cell and drivetrain losses. |

| H₂ mass required (kg) | Reserve-adjusted energy ÷ 33.33. | Core fuel requirement for the mission. |

6. Troubleshooting & FAQs

6.1 Common Issues

- Slow Loading or Freezing: If the platform is slow, first check your internet connection. H2CHAIN requires a stable, high-speed connection due to heavy data visualization and simulation processes. Try refreshing the page or logging out and back in.

- Login Problems: Ensure that you are using the correct email and password. If you forgot your password, use the “Forgot Password" link on the login page. Check spam/junk folders if you did not receive a reset email.

- Project Not Saving: Verify that you are logged in with a registered account. Unsaved projects may result from expired sessions; log in again and save frequently.

- Missing Map Layers: Some map layers depend on third-party data sources. If a layer does not load, check your browser settings (allow pop-ups and geolocation) or try switching to another browser.

6.2 Error Messages

- “Connection Lost”: The internet connection was interrupted. Reconnect and refresh the session.

- "Invalid Input Data": One or more parameters were entered incorrectly (e.g., negative values, wrong units). Review the input form and correct the highlighted fields.

- "Simulation Failed”: This may occur if project parameters are unrealistic (e.g., excessive system size without sufficient renewable resource data). Adjust input assumptions and rerun.

- "Access Denied": Your account does not have permission for this feature (beta vs. enterprise edition). Contact support if you believe this is an error.

6.3 Tips for Best Practices

- Use Supported Browsers: For the best performance, use the latest versions of Chrome, Firefox, or Edge.

- Save Frequently: Save projects at regular intervals to avoid losing work during long sessions.

- Start Simple: Run baseline simulations first before adding complex assumptions to ensure model stability.

- Check Data Consistency: Always confirm that resource, production, and cost data are in the correct units and timeframes.

- Clear Cache Regularly: Clearing browser cache helps avoid display issues after updates.

- Contact Support: For unresolved issues, use the integrated support form or email the H2CHAIN helpdesk.

7. References & Standards

7.1 Bibliography

- de León, C. M., Molina, P., Ríos, C., & Brey, J. J. (2025). Green hydrogen production's impact on sustainable development goals. International Journal of Hydrogen Energy.

- Obuseh, E., Eyenubo, J., Alele, J., Okpare, A., & Oghogho, I. (2025). A systematic review of barriers to renewable energy integration and adoption. Journal of Asian Energy Studies, 9, 26-45.

- Shanian, S., & Savadogo, O. (2024). A Critical Review of the Techno-Economic Analysis of the Hydrogen Production from Water Electrolysers Using Multi-Criteria Decision Making (MCDM). Journal of New Materials for Electrochemical Systems, 27(2).

- Dincer, I. (2023). Hydrogen 1.0: A new age. International Journal of Hydrogen Energy, 48(43), 16143-16147.

- Naanani, H., Nachtane, M., & Faik, A. (2025). Advancing hydrogen safety and reliability through digital twins: Applications, models, and future prospects. International Journal of Hydrogen Energy, 115, 344-360.

- Adeli, K., Nachtane, M., Faik, A., Rachid, A., Tarfaoui, M., & Saifaoui, D. (2024). A deep learning-enhanced framework for sustainable hydrogen production from solar and wind energy in the Moroccan Sahara. Energy Conversion and Management, 302, 118084.

- Vives, A. M. V., Wang, R., Roy, S., & Smallbone, A. (2023). Techno-economic analysis of large-scale green hydrogen production and storage. Applied energy, 346, 121333.

- International Energy Agency (IEA) – The Future of Hydrogen report.

- IRENA – Green Hydrogen: A Guide to Policy Making.

8. Appendices

8.1 Glossary of Terms

- CAPEX: Capital Expenditure, upfront costs for building infrastructure.

- Electrolyzer: A device that splits water into hydrogen and oxygen using electricity.

- Green Hydrogen: Hydrogen produced from renewable electricity through electrolysis.

- LCOH: Levelized Cost of Hydrogen, representing the average cost per kg of H₂ produced over a project's lifetime.

- Methanol (CH₃OH): A liquid fuel and chemical feedstock produced from hydrogen and carbon dioxide.

- P2X (Power-to-X): Conversion of renewable electricity into fuels, chemicals, or heat.

- PV: Photovoltaic, referring to solar power generation technology.

- Storage Tank (Type I-IV): Classification of hydrogen tanks by material and construction method.

8.2 Units and Conversions

Energy:

- 1 kWh = 3.6 MJ

- 1 MWh = 1,000 kWh

Hydrogen:

- 1 kg H₂ ≈ 33.33 kWh (Higher Heating Value)

- 1 kg H₂ ≈ 39.4 kWh (Lower Heating Value)

Pressure:

- 1 bar = 100,000 Pa

- 1 atm = 1.01325 bar